Differences Between PS, PP, and PET — Which Plastic Is Right for You?

Introduction

Plastic materials are everywhere — from the cups we drink from to the walls that decorate modern homes. Among the many types of plastics, PS (Polystyrene), PP (Polypropylene), and PET (Polyethylene Terephthalate) are some of the most commonly used.

Each of these plastics has unique qualities that make it suitable for different purposes. Choosing the right one can help you balance performance, cost, and sustainability. Let’s take a closer look at how they differ and how to select the one that fits your needs best.

What are PS, PP, and PET?

PS is a lightweight and rigid plastic known for its smooth surface and easy processing. It is often used in decorative wall panels, packaging trays, and display products. Its appearance is bright and clean, making it a popular choice for design-focused applications.

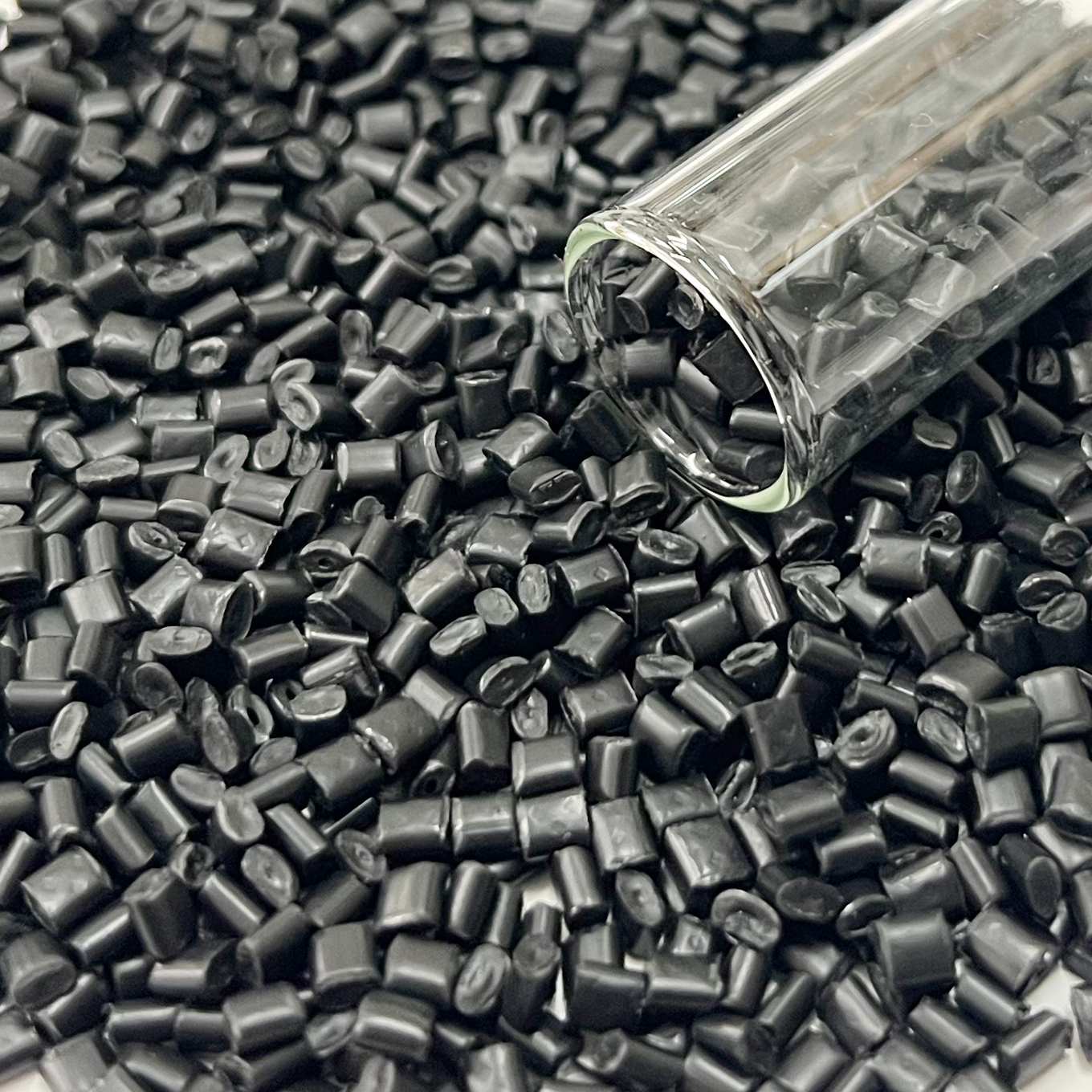

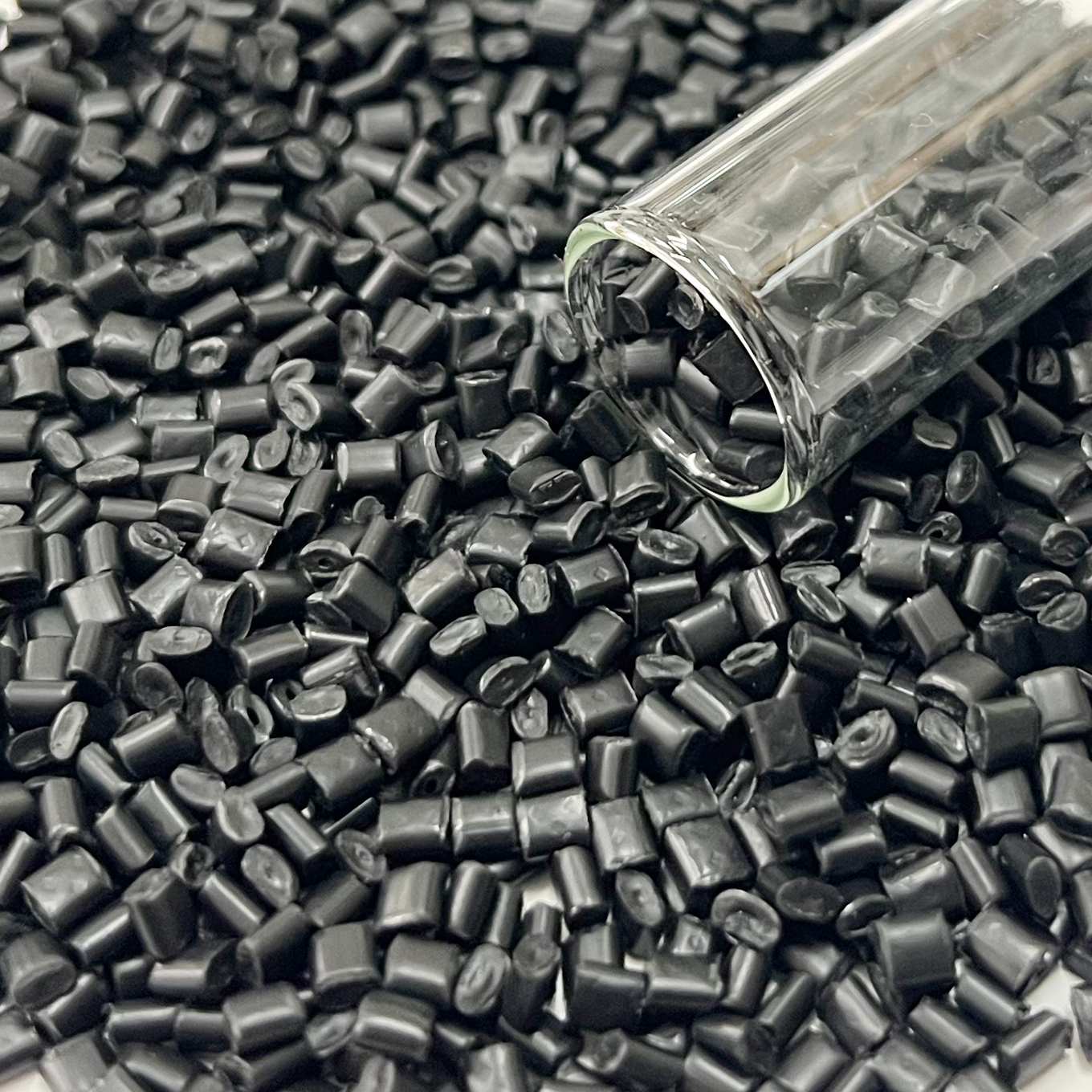

PP is a strong yet flexible material that resists heat and chemicals. It is widely used for containers, automotive parts, and industrial components. Its toughness and stability make it a reliable option where durability matters.

PET is best known for its clarity and strength. It’s the material used in bottles, food packaging, and thermoformed trays. PET is also highly recyclable, which has made it a favorite for environmentally conscious manufacturers.

Main Differences Between PS, PP, and PET

While all three belong to the plastic family, their characteristics and performance vary in a few key ways:

- Appearance: PS and PET both offer good transparency, while PP tends to be slightly cloudy or opaque.

- Durability: PP and PET are more resistant to impact and wear than PS, making them suitable for applications that require more toughness.

- Heat Resistance: PP can handle higher temperatures compared to PS and PET, which is why it’s often used for containers that hold hot items.

- Flexibility: PS is more rigid and can break under stress, while PP is flexible, and PET offers a balance between strength and stiffness.

- Recyclability: PET has one of the most established recycling systems in the world. PP is also recyclable in many regions, while PS recycling is still developing but growing rapidly thanks to new technologies.

Each material has its own sweet spot in terms of use.

-

PS (Polystyrene): Ideal for decorative materials such as interior wall panels, picture frames, and lightweight packaging. In addition, PS is also used in the construction and food industry, for example in XPS insulation boards, foam lunch box and disposable cutlery. It’s chosen for its glossy finish and ease of molding.

- PP (Polypropylene): Common in industrial containers, automotive parts, and consumer goods where flexibility and heat resistance are important.

- PET (Polyethylene Terephthalate): Dominates the packaging industry, especially for food containers, beverage bottles, and thermoforming sheets, thanks to its transparency and hygiene.

Environmental Considerations

Sustainability has become a key factor in material selection.

- Recycled PS (rPS): Increasingly used in decorative panels and household materials, giving waste foam and old plastics a new life.

- Recycled PP (rPP): Widely adopted in industrial and automotive products, helping reduce raw material use.

- Recycled PET (rPET): The most advanced recycling system, often used again in bottles, packaging, and textiles, showing strong market growth worldwide.

By choosing recycled materials, manufacturers can reduce carbon footprints while maintaining product performance and quality.

Choosing the Right Plastic for Your Needs

Here’s a simple way to decide:

| If You Need... |

Best Choice |

| A smooth, cost-effective decorative material |

PS |

| A tough, heat-resistant industrial plastic |

PP |

| A clear, food-safe and recyclable option |

PET |

When selecting materials, also consider your production process, end-use temperature, and environmental goals. The right choice not only improves performance but also enhances sustainability and brand value.

Conclusion

PS, PP, and PET each bring their own strengths to the table. PS is practical and stylish, PP is tough and reliable, and PET is clear and sustainable.

Whether you’re developing packaging, decorative materials, or industrial products, understanding these differences helps you make smarter, greener decisions.

If your business is exploring recycled plastic materials, such as rPET, rPP, or rPS, finding the right supplier can make a big difference — ensuring both quality and consistency for your production.