What Is Virgin PS?

Virgin PS (Polystyrene) is a plastic made directly from petroleum-based styrene monomers through polymerization. It is known for its clarity, rigidity, and excellent formability.

There are two main types of Virgin PS:

- GPPS (General Purpose Polystyrene) – offers high transparency and good surface gloss, commonly used in food containers and packaging.

- HIPS (High Impact Polystyrene) – enhanced with rubber to improve toughness and impact resistance, ideal for appliance housings, refrigerator liners, and electronics.

Because Virgin PS is made from new raw materials, it delivers consistent performance and aesthetic quality — but also comes with a higher carbon footprint and greater reliance on fossil resources.

What Is Recycled PS?

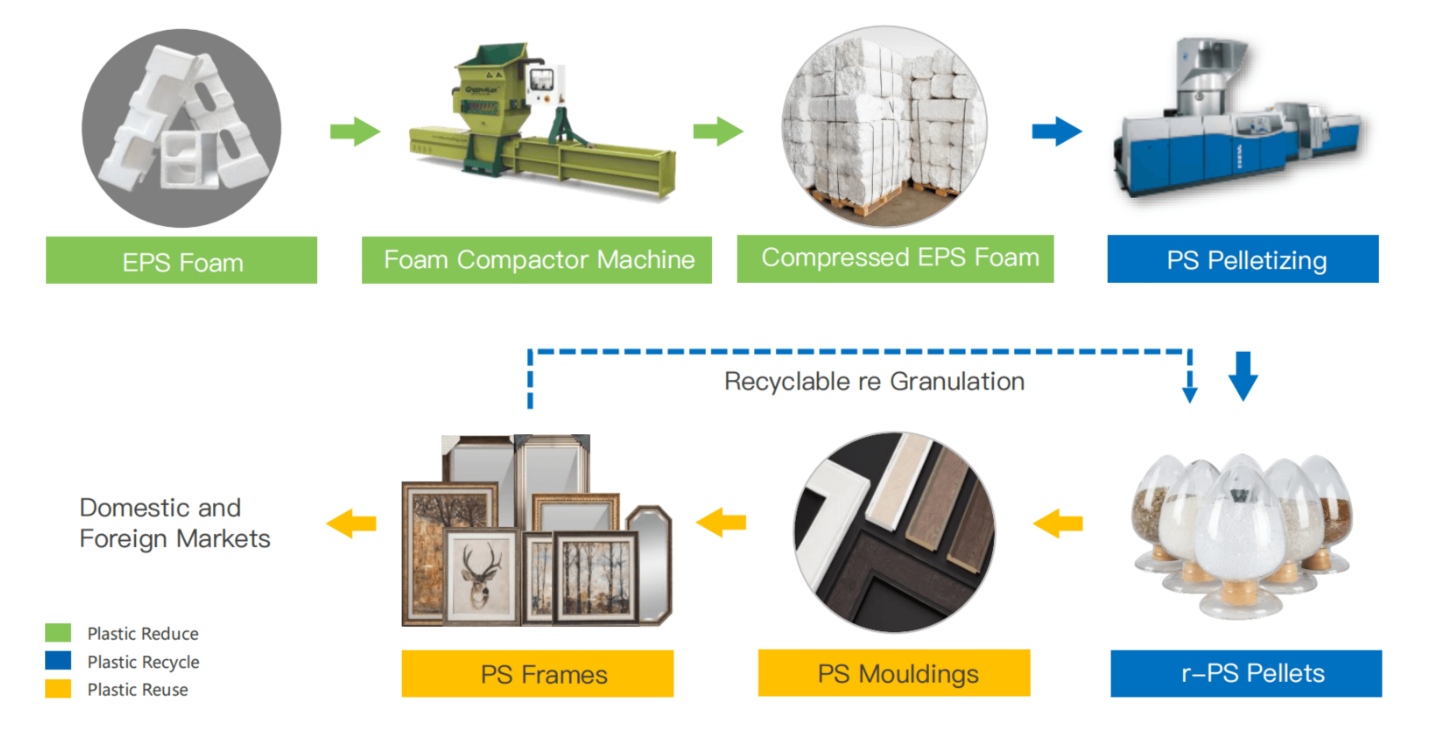

Recycled PS refers to polystyrene that has been recovered from post-consumer or post-industrial waste — such as foam boxes, packaging materials, or used plastic parts — and reprocessed into reusable pellets.

- Collection and Sorting

- Cleaning and Crushing

- Melting and Re-granulation

- Modification or Compounding (to enhance performance)

Depending on the recycling method — mechanical recycling or chemical recycling — Recycled PS can achieve different levels of purity and performance. Modern technologies now allow Recycled PS pellets to closely match the properties of Virgin PS while significantly lowering environmental impact.

Key Differences Between Virgin PS and Recycled PS

| Aspect |

Virgin PS |

Recycled PS |

| Source |

Derived from petroleum-based styrene monomers |

Made from post-consumer or post-industrial PS waste |

| Purity |

100% pure polymer |

May contain minor impurities, depending on recycling process |

| Performance |

Excellent mechanical and optical properties |

Slightly lower, but can be enhanced by modification |

| Cost |

Higher, due to virgin raw material costs |

Lower, due to waste-based feedstock |

| Environmental Impact |

High carbon footprint |

Lower emissions, supports circular economy |

| Applications |

Food packaging, electronics, medical products |

Construction materials, decorations, general consumer goods |

Recycled PS is not only a cost-effective choice but also a responsible one — aligning with global efforts to reduce plastic waste and build a sustainable future.

Environmental and Economic Benefits of Recycled PS

The shift from Virgin PS to Recycled PS brings both environmental and economic advantages:

🌿 Environmental Benefits

- Reduced Plastic Waste: Diverts PS waste from landfills and oceans.

- Lower Carbon Emissions: Every ton of Recycled PS saves energy and reduces greenhouse gases compared to producing new PS.

- Resource Conservation: Reduces dependence on petroleum-based feedstock.

- Supports Circular Economy: Encourages recycling and sustainable material use.

💰 Economic Benefits

- Lower Production Costs: Recycled feedstock is generally cheaper and more accessible.

- Regulatory Compliance: Meets growing global sustainability and recycled-content requirements (EU, U.S., Southeast Asia).

- Brand Value: Using Recycled PS enhances corporate social responsibility (CSR) and ESG performance.

How INTCO Recycling Brings New Life to PS Materials

INTCO Recycling is a global leader in resource regeneration, specializing in the recycling and reprocessing of PS, PE, PET, and PP materials.

Each year, INTCO recycles over 200,000 tons of waste plastics, transforming them into high-quality recycled pellets that rival virgin materials in performance. With six production and R&D bases worldwide, over 4,000 employees, and partnerships in 120 countries, INTCO has built a comprehensive recycling network with 1,300 collection sites across more than 100 nations.

Through advanced technology, intelligent warehousing, and carbon footprint certification, INTCO ensures that every piece of waste plastic regains new value — contributing to a greener, more sustainable planet.

Conclusion

While Virgin PS continues to play a role in precision manufacturing, Recycled PS is rapidly emerging as the smarter and more sustainable choice. With comparable performance, lower costs, and a much smaller environmental footprint, it represents the future of responsible manufacturing.

As the world accelerates toward sustainability, INTCO Recycling remains committed to driving this transformation — turning waste into resources and helping industries worldwide embrace a truly circular economy.